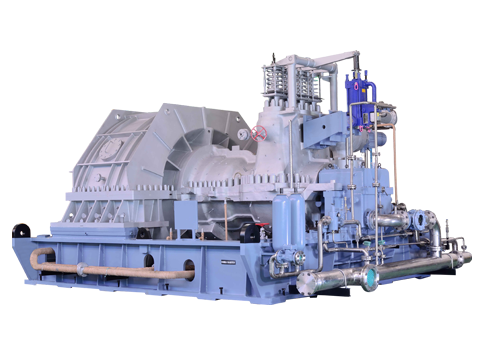

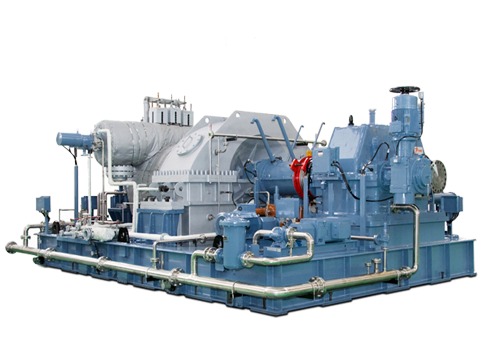

Triveni’s steam turbines finds its application in a wide range of industries such as Sugar, Steel, Pulp & Paper, Textiles, Chemical, Palm Oil, Food Processing etc. The turbines are used in multiple applications like Co-generation, Combined Heat & Power Generation, Waste to Energy, Captive Power Generation and Independent Power Generation. With the mission to provide low-cost, energy-efficient and environment friendly solutions, we invest into extensive research & development, leading to a world-class industry specific solution for every client.

With over 6000 turbines installations in over 75 countries globally, the Company is fast spreading its global footprint to more countries and geographies.