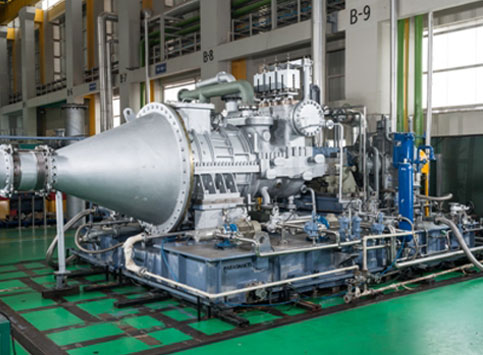

A typical waste heat recovery system with a conventional steam circuit consists of the PH (Preheater) and AQC (Air quenching cooler) waste heat boilers, a generator house with the steam turbine and the generator. The waste heat from the PH boiler and AQC are used to run the steam turbine. Triveni has the perfect selection of steam turbines, carefully designed to meet the requirements of the Cement Industry. Triveni offers Injection, Extraction, Condensing and Back-Pressure steam turbines that support the cement industry and its related application. For the cement industry depending on the AQC boiler configuration as shown in the figure, Triveni customizes the steam turbine for single or double injection. For the steam injection configuration, Triveni offers a robust control system that is specifically designed for the cement industry. Triveni can provide both impulse and reaction technology solutions for heat and power applications for the cement industry.