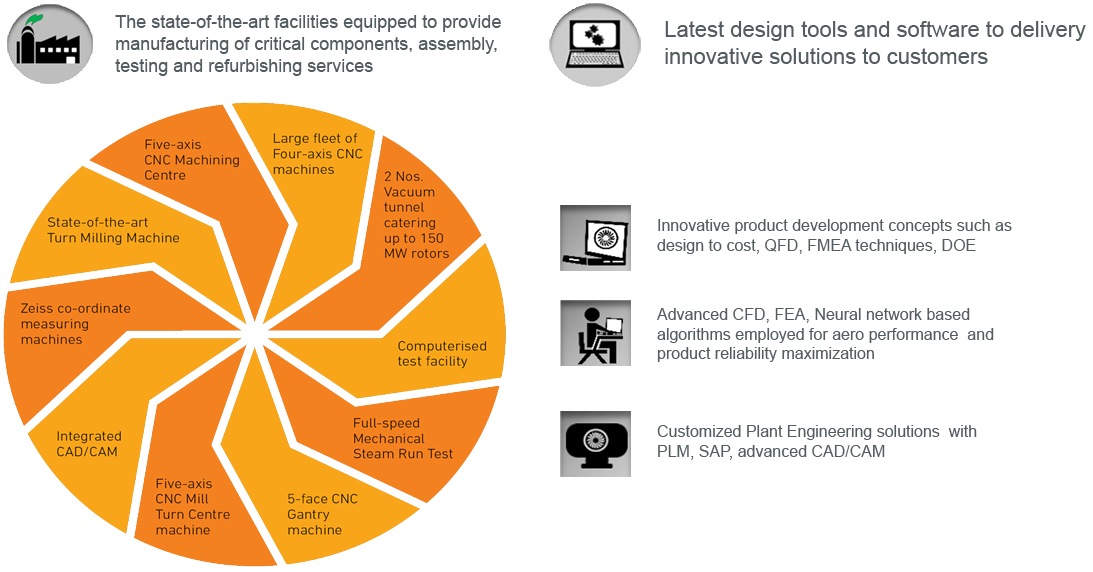

The manufacturing and assembly of a steam turbine involves high level of precision engineering employing numerous components and sub-assemblies. The mechanical integrity and tolerances are very critical to the product performance, efficiency and reliability. The state of the art manufacturing processes and machinery are deployed for in-house manufacture of critical components such as casings, rotors, blades, labyrinth packing and oil seal holders. The manufactured turbines undergo extensive quality checks and precision tests. Triveni is amongst the few turbine manufacturers worldwide, which conducts mechanical steam run tests. Engineers ensure that the turbines maintain mechanical integrity, operational safety, and over-speed limits in no load conditions prior to product dispatch to the site.