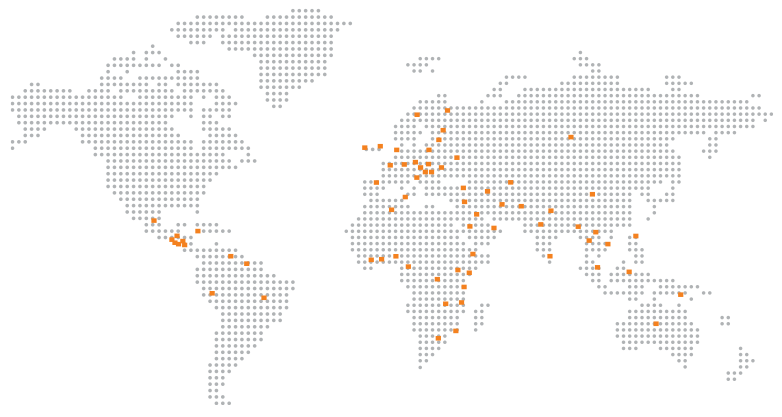

Having an experience of Manufacturing, Installing and Commissioning of about 6000 Turbines in over 80+ countries, our in depth knowledge of working of Steam Turbines is unparalleled. Our experts study the customer's new requirements and we undertake the Re/Reverse Engineering of your existing Turbine incorporating latest advanced equipment within the existing boundary conditions. We upgrade your control systems to suit your new requirements. Conversion of Mechanical Governing system to Electronic Governing system.