The palm oil industry is one of the leading industries in the South East Asia region. Indonesia is the leading producer and exporter of palm oil. India is one of the key players in importing and manufacturing palm oil. Triveni has produced a significant impact on India's palm oil industry in a short span of 2 years.

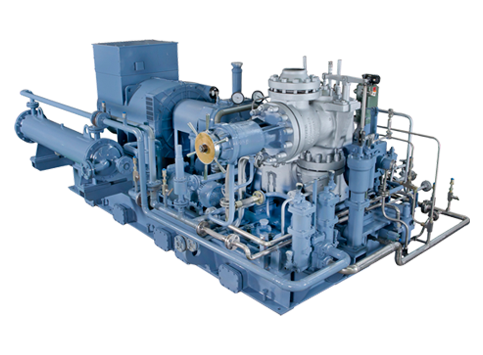

Triveni offers the perfect selection of steam turbines, carefully designed to meet the requirements of each oil mill. The steam turbines also vary in size to comply with individual operating parameters. With a total installed base of over 130 steam turbines and more than 60 multi stage steam turbine units installed, Triveni has an established customer base in countries - Malaysia, Indonesia, Thailand and Latin America of its reliable and robust Steam Turbine solutions offering multiple benefits.